Custom Process

We combine this intelligence, creativity and assets with our expertise in toy design and manufacturing. We then recommend customized toy and collectible concepts that address your team's goals and challenges. ODM and OEM are supported.

Initial packaging concepts are also taken into consideration, as well as all aspects of the final toy. We consider all possible ways to maximize fan excitement and joy.

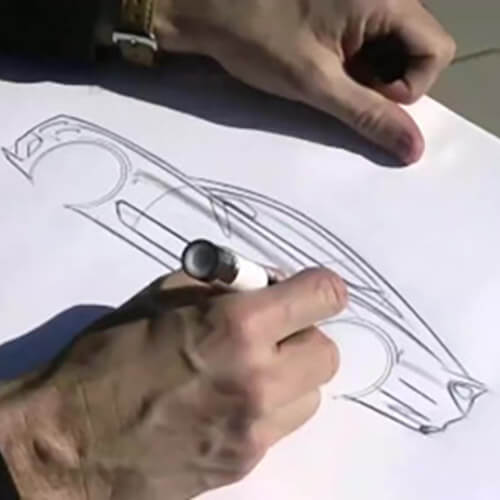

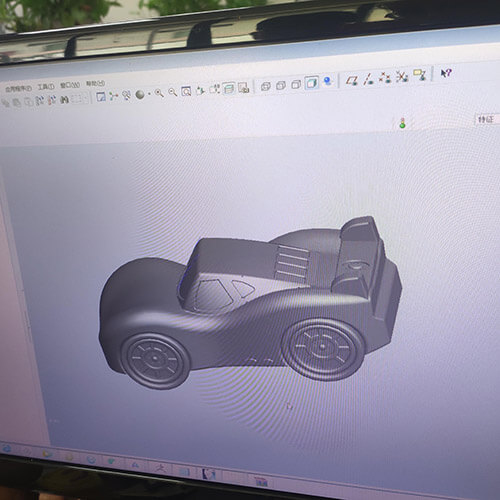

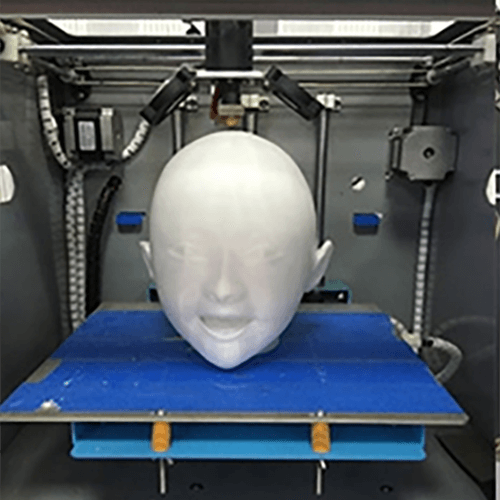

With an approved concept, we completed the design of the toy from top to bottom. We then start making prototypes using a mix of 3D modeling, rapid prototyping, hand sculpting, molding and casting. Once the model, sculpture or pattern is approved, we create painted prototypes and begin designing the packaging.

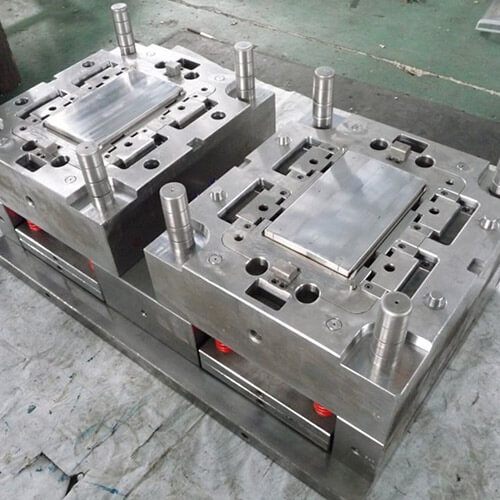

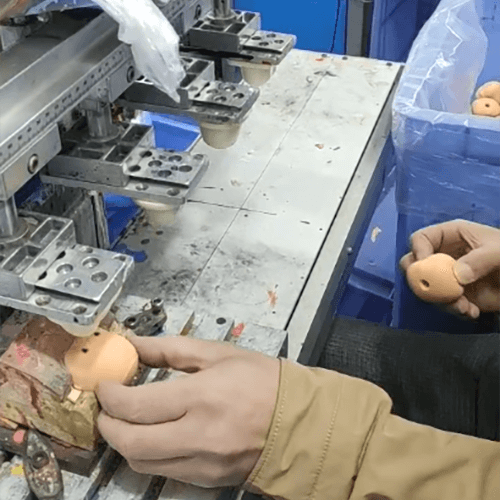

We make the toys & collectibles from a variety of materials. First we fabricate all individual parts, then finish (paint, sew, print, etc), assemble and package.

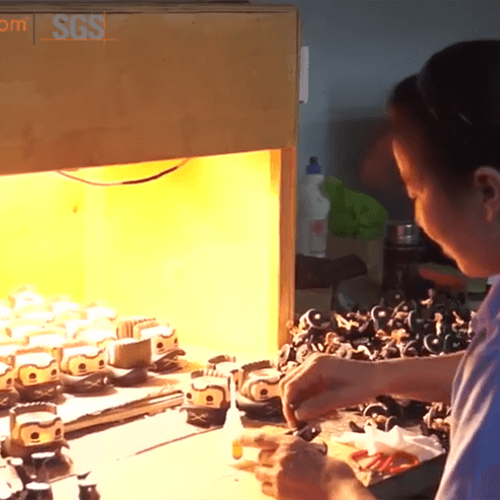

Obsessive about quality we perform multiple QC tests & reviews, including independent third-party inspections. We also complete all required safety testing.

After the toys have been inspected for quality and packed in cartons, they’re loaded onto a boat or plane on their journey to you and your fans’ hands.

Over the years we've managed shipments to most corners of the world - borders don't scare us, nor do complex distributions or deliveries to faraway warehouses and convention centers at ludicrous speed.